Many advantages of the twin-shaft concrete mixer indicate that it is an ideal machine for the production of concrete mixtures. This is the best choice for performance and reliability for concrete batching plant.

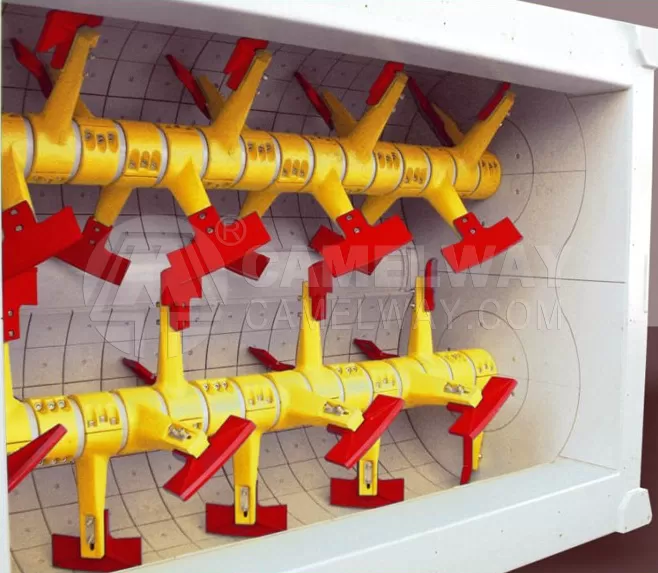

The twin-shaft concrete mixer consists of a stationary drum with two horizontal shafts located inside.

Blades are mounted on the shafts in a spiral, allowing the mixture to be screwed along the shaft, while on each shaft in different directions.

At the end of each shaft, the blades are located in the opposite direction to transfer the mixture to an adjacent shaft.

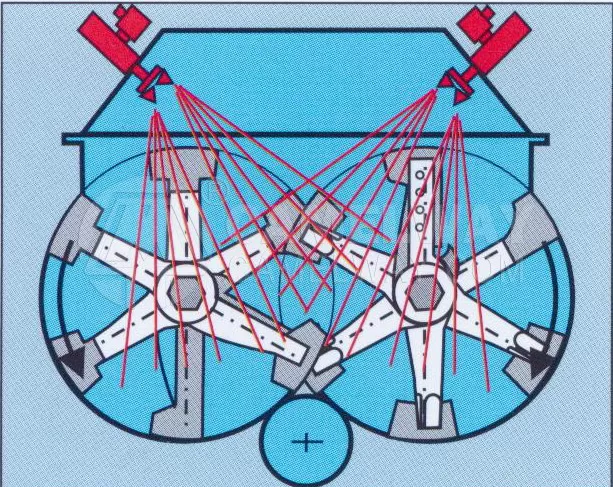

This design makes the mixture move in an annular manner along the mixer, while moving in a screw-like manner, turning inward. This leads to intensive movement of the mixture in three directions at once.

Both mixing circles intersect in the center of the mixer tank. There is a highly turbulent zone, further enhancing mixing effect.

In addition to reducing mixing time, this saves energy, reduces the wear of the mixer as a whole and provides a gentle mode for the mixture.

Water is supplied from the water supply network; a water dispenser can be equipped.

Most of the concrete mix is discharged by gravity when the discharge door is opened, the remainder is fed to the discharge window with mixing blades. Therefore, the likelihood of delamination of the mixture is very small.