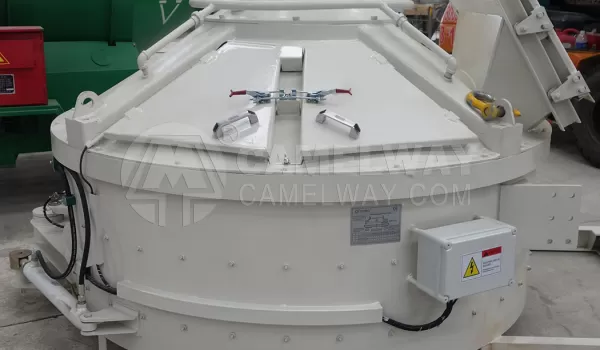

The planetary concrete mixer is a compulsory concrete mixer that drives the main shaft to rotate by the overhead motor. The stirring device on the stirring shaft can rotate and rotate around the central axis to ensure no dead angle during the mixing process. The unique blade-type blade allows the material to move in both horizontal and vertical directions, which is more conducive to breaking the agglomeration of the cement particles, making the bonding between the molecules better, and achieving uniform mixing of microscopic meaning.

This mixer type distinguishes itself by a rotor that turns around a vertical central axis and is fitted with 1 or more rotating mixing stars, depending on the mixer size. Because the offset rotational axis of the mixing stars the individual mixing tools of the mixing stars form a sort of planetary path.

Planetary Concrete mixer Offers unmatched mixing homogeneity, Camelway's planetary mixers are designed to meet the high quality concrete demands of customers involved in special applications such as precast or low slump concrete.

Planetary Concrete Mixer is an ideal equipment in the block-making and concrete precast industry, whcih is particularly suitable for the production of the following concrete types:

- Face and core concrete

- Normal concrete

- Light-weight concrete

- Heavy-weight concrete

- Self-compacting concrete

- Self-compacting light-weight concrete

- Ultra-high performance concrete

- Special products such as foamed concrete

ADVANTAGES OF PLANETARY MIXERS

- Due to planetary mixing action, lesser mixing time is required

- More homogenous mixture is obtained due to compulsory mixing action

- Low wear and tear of parts due to liners present

- Highly efficient in terms of power consumption

| Model | Discharging Volume | Diameter of Mixing | Total Weight | Mixing Power | Discharging Power |

| (L) | Drum(mm) | (kg) | (kw) | (kw) | |

| JN250 | 250 | 600 | 1200 | 11 | 2.2 |

| JN330 | 330 | 800 | 1700 | 15 | 2.2 |

| JN500 | 500 | 1200 | 2000 | 18.5 | 2.2 |

| JN750 | 750 | 1800 | 3500 | 30 | 2.2 |

| JN1000 | 1000 | 2400 | 6000 | 37 | 3 |

| JN1500 | 1500 | 3600 | 7000 | 55 | 3 |

| JN2000 | 2000 | 4800 | 8500 | 75 | 4 |

| JN2500 | 2500 | 6000 | 10500 | 90 | 4 |

| JN3000 | 3000 | 7200 | 11000 | 110 | 4 |