Dust collectors are mainly divided into three categories: water dust removal, electric dust removal, pulse dust removal.

1. water dust removal

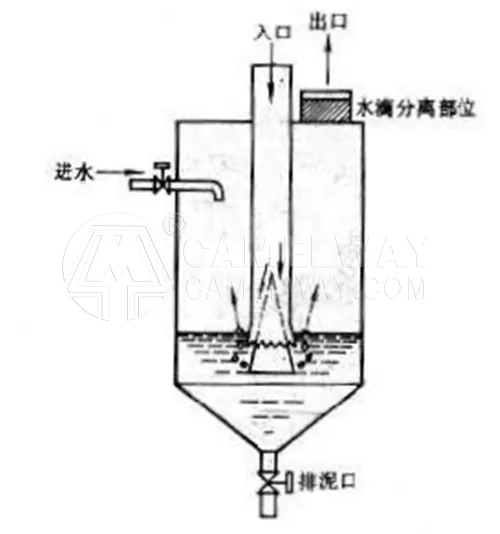

Water dust collector is a device that makes dust-containing gas and liquid (water usually) come into close contact, uses the inertial collision of water droplets and particles and other effects to trap or enlarge particles, and separate dust from flue gas. The water dust removal system is also a relatively mature dust removal method. The main body of the simple water dust collector is just a water tank with a water storage tank at the bottom. It is filled with clean water. The dust-containing gas drawn by the induced draft fan is sprayed into the water tank, and most of the dust will flow into the water storage tank at the bottom of the water tank, and after a long period of time, sedimentation and mud will be deposited at the bottom of the water tank.

Replacement cycle: no need to replace under normal circumstances.

2. Electrostatic dust removal

Electrostatic precipitator is a dust removal device that uses a strong electric field generated by a high-voltage DC power supply to ionize gas and generate corona discharge. Under the action of the electric field force, suspended dust particles are separated from the gas and captured. The dust particles in the airflow are charged by the corona discharge generated by the two fishbone discharge electrodes of the cathode row. Due to the effect of negative ions, the charged particles are captured by the anode row under the action of the power plant. In the ionization zone, they are charged by the action of positive ions. The dust particles are collected by the auxiliary electrode arranged on the anode row, and the vibration device periodically vibrates the radius attached to the anode and cathode rows into the ash hopper.

Replacement period: 3-6 months.

3. Pulse dust collector

Pulse dust collector, when the dust-laden gas enters the dust collector from the air inlet, it first encounters the inclined plate and baffle in the middle of the air inlet and outlet, and the airflow turns to flow into the ash hopper. At the same time, the airflow speed slows down. Due to inertia, coarse particles in the gas are caused The dust flows directly into the ash hopper. It plays a role of pre-collection of dust. The airflow entering the ash hopper is then folded upwards and passes through the filter bag with a metal skeleton inside. The dust is trapped on the outer surface of the filter bag. The purified gas enters the upper clean room of the filter bag chamber and is collected to the outlet. The air outlet is discharged, and the dust-laden gas is purified through the filter bag. As time increases, more and more dust accumulates on the filter bag, which increases the resistance of the filter bag, resulting in a gradual decrease in the processing air volume. In order to work normally, control The resistance is within a certain range. Once it exceeds the range, the filter bag must be cleaned. When cleaning, the pulse controller will trigger each control valve to open the pulse valve in sequence. The compressed air in the air bag will be sprayed from each hole of the blowing pipe through the venturi to each corresponding In the filter bag, the filter bag instantly expands rapidly, so that the dust accumulated on the surface of the filter bag falls off, and the filter bag returns to its original state. The cleaned dust falls into the ash hopper, and is discharged from the body through the ash discharge system. As a result, the dust accumulated on the filter bag is periodically pulsed to clean the dust, so that the purified gas can pass through normally and ensure the operation of the dust removal system.

Replacement cycle: about one year

\

\

If you want to know more about these equipment, just contact me.

Bonnie Yang, mob: +86 17839193601, email: [email protected].