Concrete batching plants don’t need any introduction. Nowadays these plants have become an ideal source of fast concrete production for the construction companies. No matter your business is small or big? Batching plant machinery installation has become mandatory for every construction site owner to do the task of construction effectively. In this blog, we are going to share the information and answer of how to measure aggregate moisture in a mobile concrete batching plant. If you are also looking for the answer to this question then this blog will surely help you. Without any delay let’s start Defining the right moisture of aggregate in the mobile batching plant is the most crucial aspect for the users. You can’t do this task without any inappropriate knowledge and information.

Calculations of Aggregates in Water to Add in Concrete Batching Plant

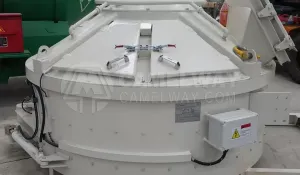

You must have the real-time information of the moisture aggregates for effectively using aggregate moisture values for the calculations of material quantity. First of all both moisture percentage and water amount contains in the aggregated extensively attract the water material and consistency and the quality of the concrete mixer also important at the same time. The right amount of dosing of water as per the target W|C-respectively and W|B Value. The amount of water which you want to add in the concrete plant should be set according to the real mix design and we all know total water contains different aggregate fractions through which we can easily calculate the right amount of water for dosing from the water scale and jointly combined with the mixture.

Here is the Example for You!

If you have the Mobile Concrete Batching Plant of 3 m3 in which the amount of aggregates is around 6000KG and the amount of aggregate moisture is 4% the amount of water in the aggregates is 240 KG. Here the deviation of aggregate moisture is -+1%. On the other hand, the variation of water amount is plus or minus 60 KG.

What does Will happen With Inaccurate Moisture Measurement in Plant?

Well, if your site workers are doing inaccurate moisture measurement in the Concrete Batching Plant then it may also create the problem of manual water reduction or dosing extra water quantity on the ampere meter visible the power used by the mixer motor. This may also increase the chances of inconstant consistency and produce base concrete quality and also increasing mixing time in the plant. Therefore, it will also affect the production capacity of the plant. No matter you are using a Concrete Plant or RMC Plant you must do the task of this reduces the production capacity and generates unnecessary wear in the mixer.

Types of Moisture Measuring Sensors of Concrete Plant

You can also buy the moisture measuring sensors for making this task easier and faster for the measurement of aggregates with water in the batching plant and major sensors are Radar sensors, Microwave sensors, and Optical sensors