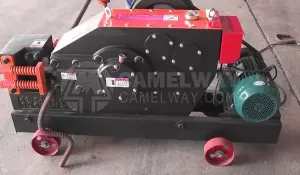

Let’s look at an example. Your builder has just started excavating the foundation pad and floor for your new factory. Naturally, you’re very excited about the project starting and the prospect of being up and producing concrete products to fulfill orders coming. But then you get a knock on the door by the contractor asking how you would like to pay the hauling fees for disposing of the dirt. This was never discussed during the entire sales process, and you become irate at having to pay an additional $500-$2,000 you were not planning on. There are many such scenarios that become a reality every day…this is what we’re trying to avoid in your planning and installing of a complete building concrete batching plant.

Most Common Hidden Costs:

- Dirt Hauling In/Out during construction phase

- Electrical Hook-ups to main panel, individual equipment

- Fencing and properly to secure equipment

- Landscaping outside the building if located in a city

- Shipping skids purchase for startup phase of business

- Drainage work in storage yard if needed

- Welder and cutting torch purchase

- Tools required for maintenance purchase

- Hitting round water or hard bedrock during

How to Avoid Hidden Costs?

We will disclose all potential costs and clearly specify what is and is not included in our installer’s scope of work. I make it a point of discussions as early in the buying process as possible for you.