Operating Costs is a matter of paramount concern for every investor in Concrete Batching Plants. Thoughtful planning can enhance the company's competitiveness and facilitate rapid development. Today, we will analyze a more accurate method of cost calculation.

Raw Material Costs for a Concrete Batching Plants:

This encompasses the expenses associated with all materials such as cement, sand, gravel, fly ash, mineral powder, admixtures, etc. These can be relatively easily calculated based on the mix ratio and the unit price of raw materials.

Freight:

This primarily includes the fuel consumption of various vehicles, encompassing the costs of concrete mixer trucks, concrete pump trucks, loading trucks, etc., which can generally be calculated through statistical analysis.

Employee Wages:

Generally, the total wages of employees in Concrete Batching Plants are linearly related to production volume. This is contingent upon wage levels in different regions and the circumstances of each enterprise.

Depreciation of Concrete Batching Plants Equipment:

This necessitates consideration of the depreciation period. For instance, if the company establishes a five-year cost recovery period, it entails dividing the total equipment cost by the five-year expected output, resulting in the equipment depreciation cost per cubic meter of concrete.

Marketing Expenses:

These encompass all expenses incurred by the marketing department during the sales process of the Concrete Batching Plants (e.g., catering, entertainment, rebates, etc.), which should be kept within a certain range.

Water, Electricity, and Communication Costs:

These include the expenses associated with water, electricity, and communication incurred during the production process of the Concrete Batching Plants and the daily activities of employees within the unit. They are relatively fixed.

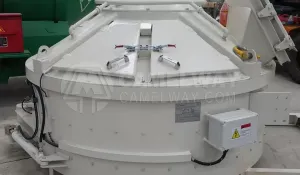

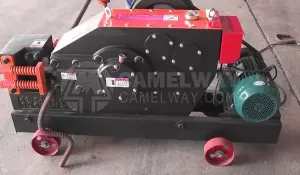

Consumable Costs:

These involve the expenses related to specific consumables for Concrete Batching Plants companies, such as concrete pump truck pump pipes, S valves, etc., concrete mixer truck oil, oil filtration, air filtration, tire consumption, etc. (also applicable to pump trucks, loading trucks, etc.), forced concrete mixer liners, concrete mixing arms, engine oil, etc.

Inspection Costs:

Primarily consisting of annual inspection fees for Concrete Batching Plants, floor scales, and testing equipment, as well as inspection fees at inspection stations.

Other Expenses:

These encompass taxes, office consumables, network fees, GPS fees, ERP fees, etc.